Ball Warper

In-Line Creel

- Accommodates wide range of package sizes.

- Equipped with various tension devices ranging from post and disc to electronic.

- Available stop motions include drop wire, motion sensing and optical sensing.

- Over head traveling cleaner or lint fans.

- Transfer magazine, Swing gate, Trolley or Nonmagazine type creel available.

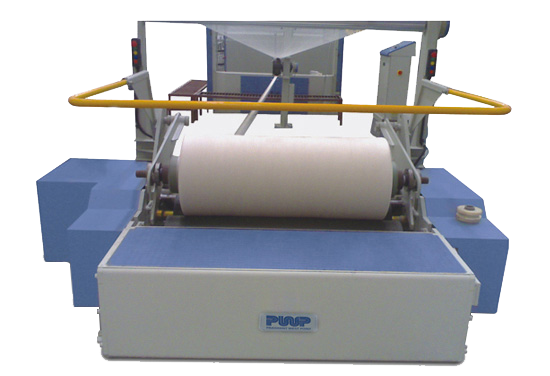

MBW-4800 Ball Warper

- Heavy-duty flame cut steel side frames and cross members.

- Stainless steel doffing platform eliminates potential damage to the ball.

- Equipped with frequency controlled AC drive designed for a gear-in speed of 500 MPM.

- Rubber covered drive/bed rolls minimize yarn damage and ensures silent operation.

- Light weight trumpet carrier reduces noise and traverse mechanism wear.

- Aircraft type pneumatic brake used for quick response.

- Low mass yarn carrier is chain and sprocket driven on dual shafts for reduced vibration and noise.

- Servo motor and drive used to alter the rope-winding pattern. It facilitates to set the optimum traverse speed and allow for change of the traverse speed. This helps to reduce vibration as the diameter built up of ball warp gets increase.

- Traverse drive speed has absolute synchronization with drive rolls.

- Standard air cylinders are used for loading the ball, thus reducing maintenance and simplifying the pneumatic circuit.

- Ergonomically design of the ball warp hooks simplifies the automated doffing process.

- All controls enclosed in console for protection from dust and contamination.

- Remote Diagnosis - online support from our Service head Office